At PEL Manufacturing, we specialize in helping businesses, schools, and print shops create professional-looking documents with spiral coil binding. Understanding the essentials is critical when choosing the right binding supplies and equipment.

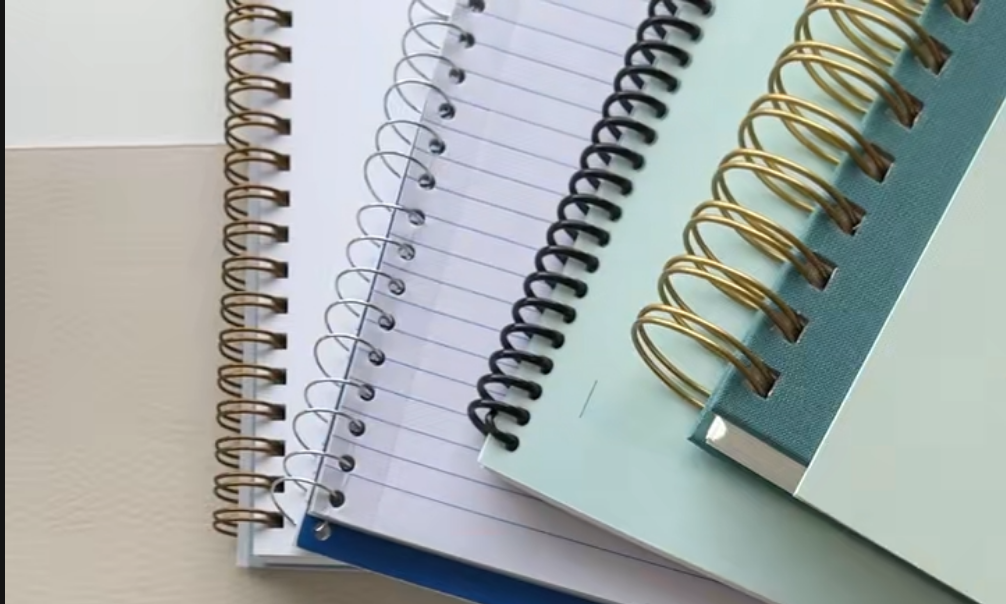

1. Spiral Coil (or Coil Binding): A durable plastic or metal coil that threads through small holes punched along the edge of a document. It allows pages to turn smoothly and lay flat. Spiral coils are flexible, lightweight, and available in a wide variety of colors and sizes.

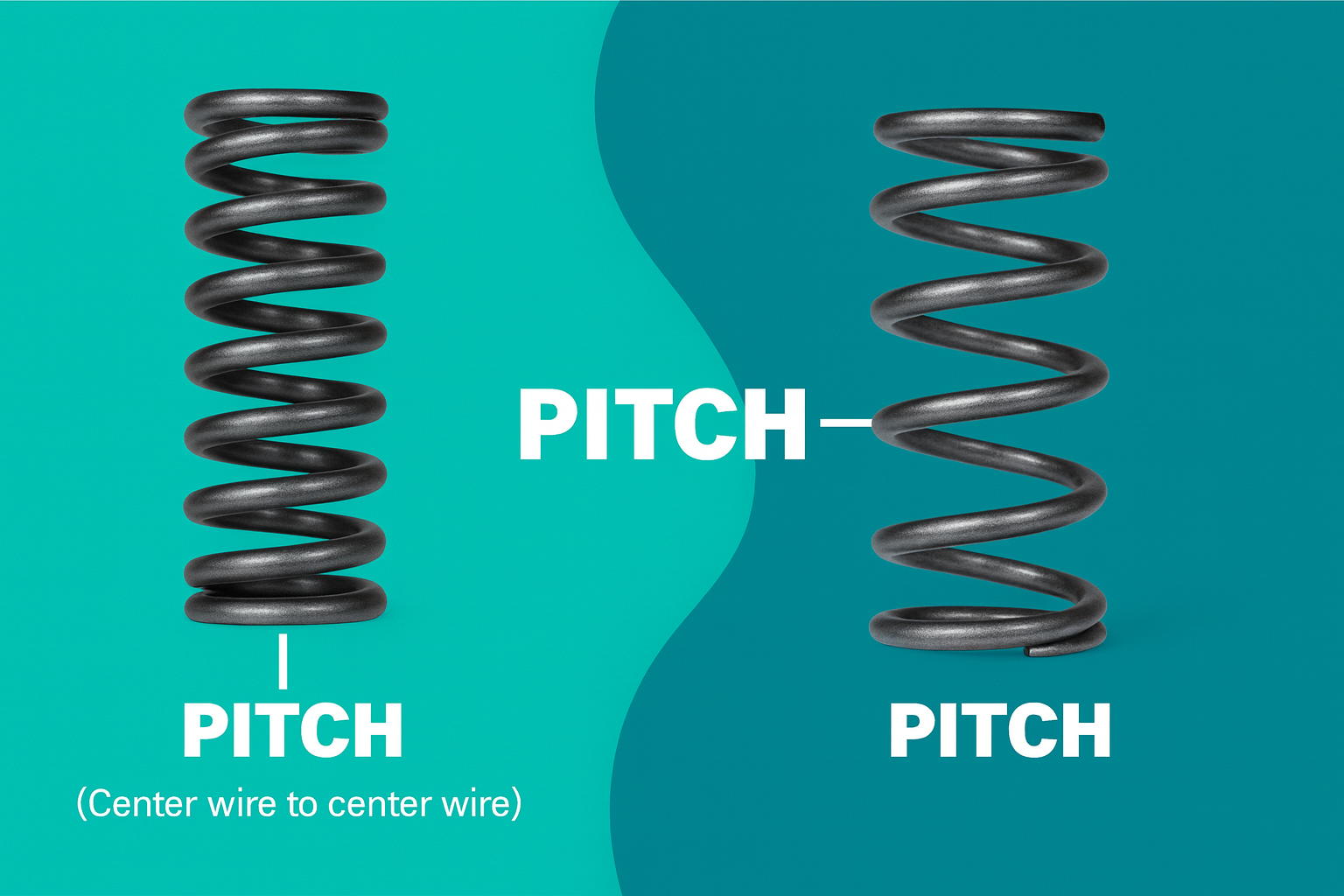

2. Pitch: Refers to the spacing of the holes punched into paper. The most common are:

- 4:1 Pitch – 4 holes per inch, fits standard plastic coils (the most widely used option).

- 5:1 Pitch – 5 holes per inch, less common but sometimes used for specialty applications.

(Pro tip: Always match coil pitch with punch pattern of the binding machine).

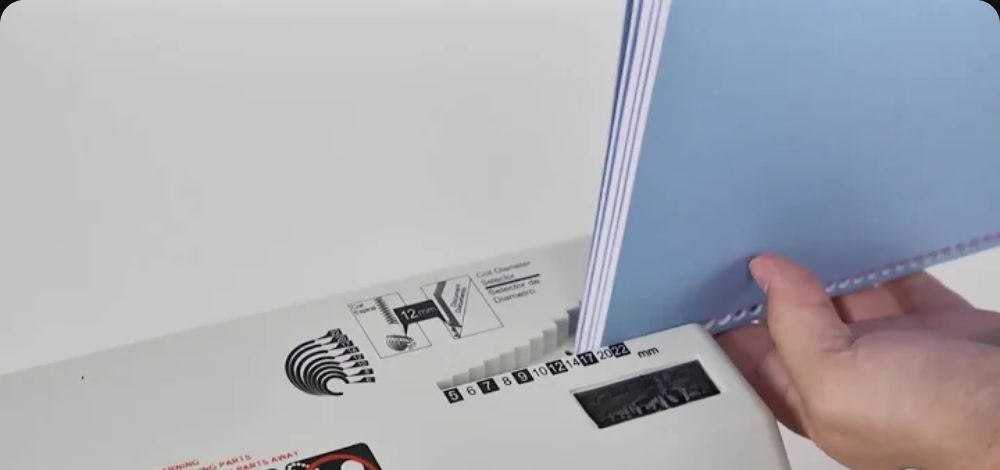

3. Coil Diameter: Thickness of spiral coil must match thickness of the document. Coils are measured in millimeters or inches, from small sizes (6mm-thin booklets) up to large coils (50mm+ for thick manuals).

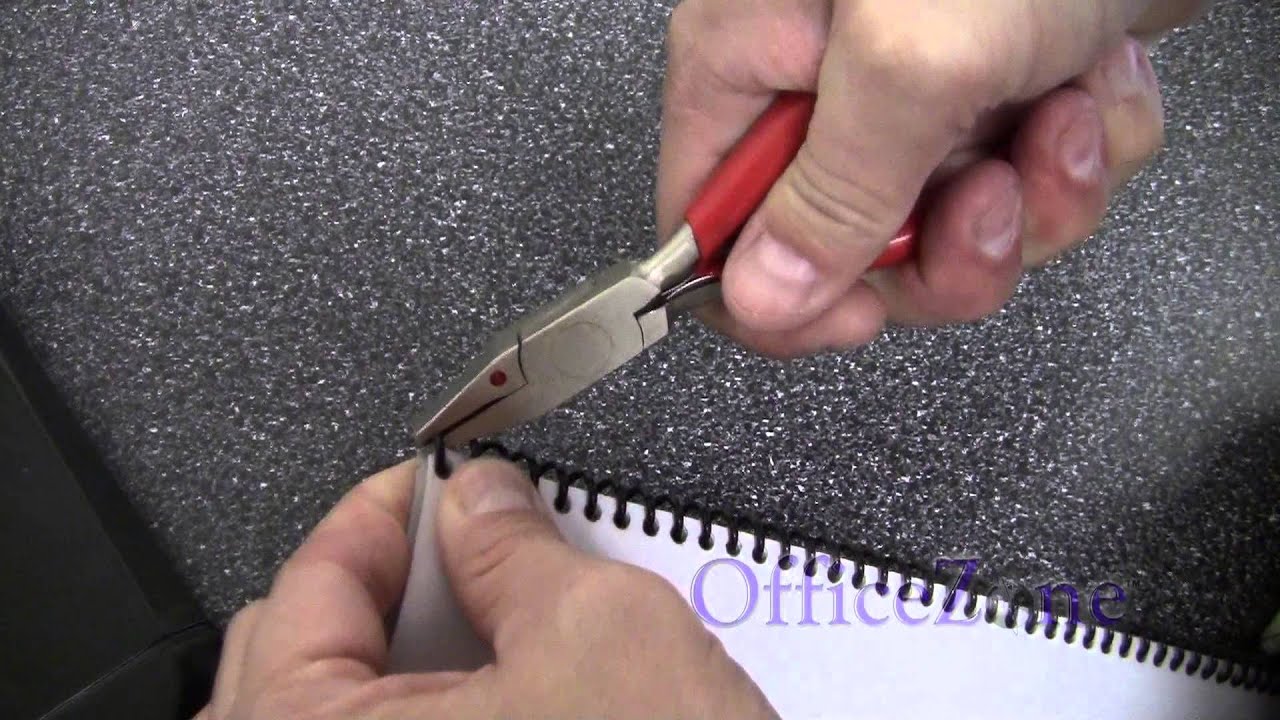

4. Coil Crimping: The process of cutting and bending ends the coil after insertion, so it doesn’t spin out of the document. This step is critical for securing the binding. Specialized coil crimping pliers are used.

5. Coil Insertion: The step where the coil is threaded through the punched holes. This can be done:

- Manually – by twisting the coil through by hand (best for small jobs).

- With an Electric Coil Inserter – which spins coil into place, saving time for larger volumes.

6. Punch Pattern: The series of holes punched into the paper. For spiral coils, the holes are typically round or oval. Oval holes are preferred for larger coil diameters, as they make insertion faster and easier.

7. Binding Edge: The side of the document where holes are punched and the coil is inserted. The binding edge size determines the maximum sheet capacity and coil diameter you’ll need.

8. Sheet Capacity: How many pages a specific coil size can hold. For example, a 6mm coil holds about 25 sheets, while a 25mm coil can bind up to 220 sheets. Matching coil size to your project ensures a clean, professional look.

9. Finishing: The last step in the process of cutting, crimping, and checking the document so coil is secured, and the pages turn smoothly.

At PEL Manufacturing, we provide high-quality spiral coils, crimping tools, and binding equipment designed to make the process smooth and efficient for businesses of all sizes.